Polyurethane Modular Screen Panel

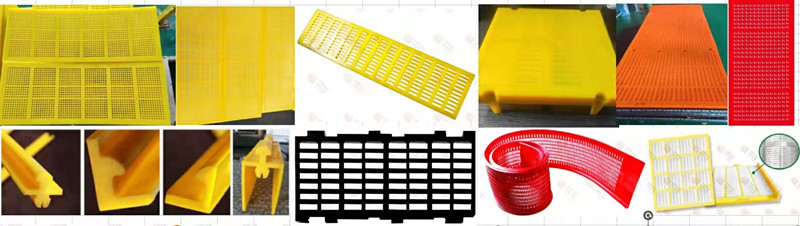

Feature

● Super wear resistance, light weight and high separation efficiency.

● Non-plugging, anti-friction, anti-impact, anti-tearing, long using life, low noise, easy installation.

● Small maintenance workload, low cost and improving the high production efficiency. It is a new generation replacement of the steel platepunching screen mesh, steel wire woven screen mesh, stainless steel screen mesh and rubber screen mesh.

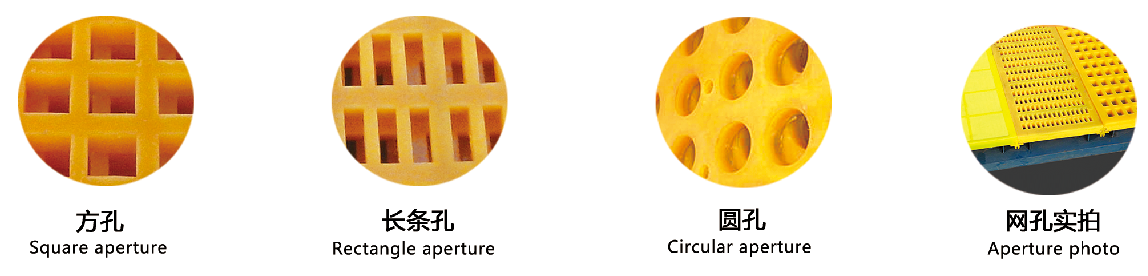

Aperture

Various types apertures (slots/meshes) all can be designed as clients’ requests.

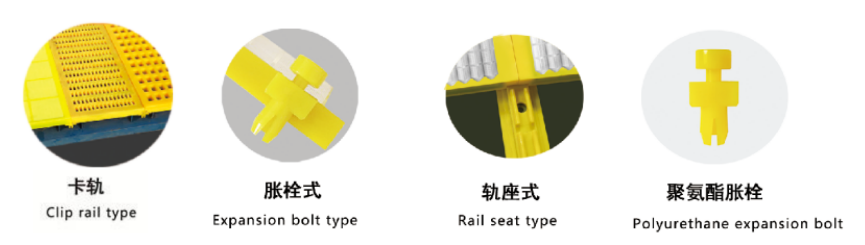

Installation

The installation types include clip rail type, rail seat type and tension type, easy to install, disassemble and replace.

Technology Core

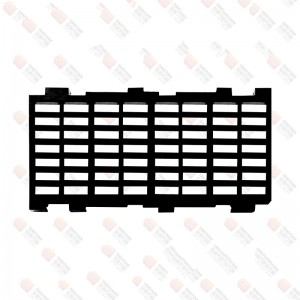

● The screen panels are blanked out and reinforced over the support bar areas to prevent from wearing and ensure the installation.

● The impact areas are blanked out and made thicker.

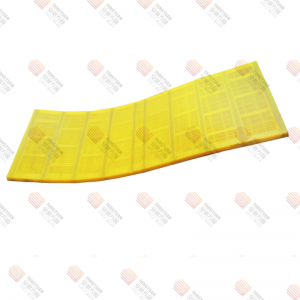

● There are the reinforcement strips on the screen panels to ensure the correct tension and keep the shape u-nder the load.

● The edges of screen panels have been machined and reinforced, which can make a perfect seal between screenp-anels.

● Bolt down holes are designed in appropriate places to ensure the accurate center location.

● The slots of the screen panels are tapered in design, no blinding and high efficiency.