2022 Latest Design Coal Screening Process - Polyurethane Tensioned Screen Panel – Fangyuan

2022 Latest Design Coal Screening Process - Polyurethane Tensioned Screen Panel – Fangyuan Detail:

Advantage

Application

The polyurethane tensioned screen panels are widely used in metallurgy, mining, coal, building materials, water conservancy, road building and other industries.

Advantage

Polyurethane Tension Screen Panels have long service life and large bearing capacity. Because polyurethane screen itself has very high elastic modulus, high strength, impact absorption and high wear resistance, it has high tensile strength. Its bearing capacity is more than 2.5 times that of rubber screen panels, so its service life is 8-10 times higher than that of metal screen mesh. The screen surface has self-cleaning performance, no hole plugging and high screening efficiency. Due to its strong water permeability and large cone angle of screen hole, polyurethane can effectively prevent the adhesion of wet fine particles, so it is suitable for the screening and classification of wet fine particles.

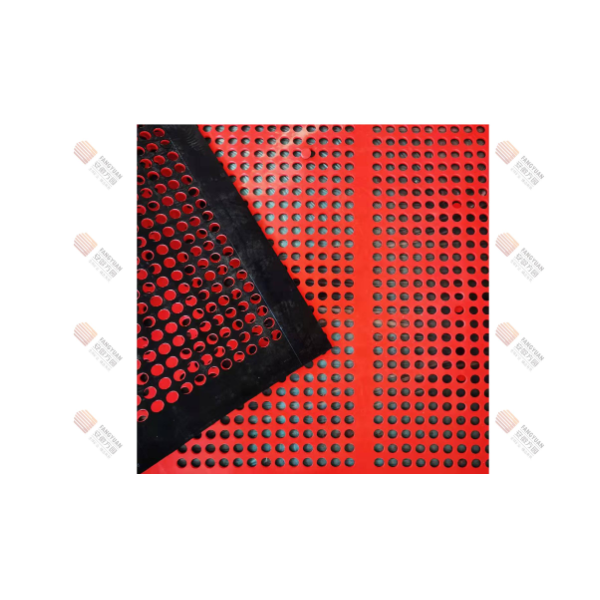

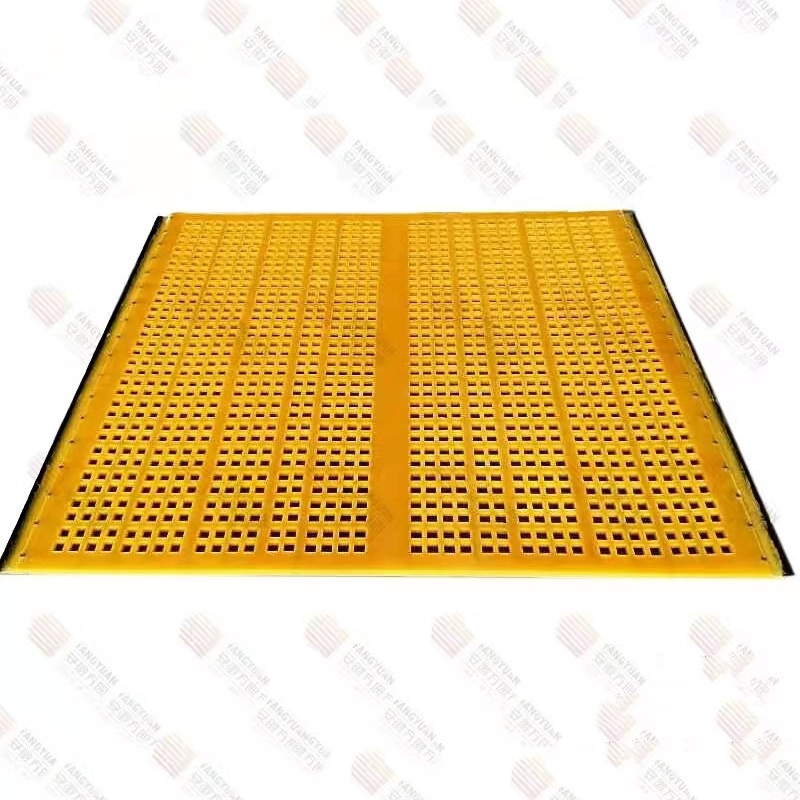

Product detail pictures:

Related Product Guide:

Now we have superior devices. Our solutions are exported to your USA, the UK and so on, enjoying a superb name between customers for 2022 Latest Design Coal Screening Process - Polyurethane Tensioned Screen Panel – Fangyuan , The product will supply to all over the world, such as: Denmark, Maldives, Hungary, We'll initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.